Selecting the appropriate vertical water tank is crucial for ensuring an efficient and reliable water supply system. Determining tank capacity process involves taking into account factors such as maximum water usage, available space, and potential modifications.

An experienced technician can assist in performing a comprehensive analysis to determine the ideal tank dimensions for your specific requirements.

It's important to choose a tank material that is durable.

Popular choices include steel, fiberglass, and concrete.

Here are some key factors when identifying a vertical water tank:

* Consumption requirements

* Dimensions and storage

* Material and construction

* Accessibility and site conditions

Designing Horizontal Tanks for Industrial Use

When planning horizontal tanks for industrial applications, various factors must be thoroughly considered to ensure optimal performance and mechanical integrity. The choice of material is contingent on the specific contents being stored, with considerations given to corrosion resistance. Tank dimensions determine capacity and must be tailored based on volume requirements. ,Additionally, design parameters must comply with relevant industry regulations to ensure safety and compliance.

- Tank durability

- Chemical resistance

- Gas management

Enhancing Rainwater Harvesting Systems with Efficient Storage Tanks

Rainwater harvesting systems are becoming increasingly popular as a sustainable and cost-effective way to conserve water. A key component of any successful rainwater harvesting system is the storage tank. Selecting an efficient storage tank and optimizing its design can significantly affect the overall performance of the system. Factors to consider when choosing a storage tank include the estimated volume of water, the composition of the tank, and its placement. Adequately sizing the tank ensures that enough water is collected to meet requirements, while using durable materials safeguards against leaks and corrosion. Placing the tank in an convenient location facilitates easy service.

- Furthermore, integrating a filtration system into the storage tank can purify sediment and debris, improving water quality for various uses.

- Implementing a first-flush diverter can prevent the initial runoff from entering the storage tank, which often carries contaminants.

- Periodic maintenance of the storage tank, including cleaning and inspection, is essential for ensuring its longevity and performance.

By optimizing rainwater harvesting systems with efficient storage tanks, homeowners and businesses can conserve water resources, reduce their environmental footprint, and may also lower their water bills.

Determining the Right Storage Tank Material for Your Needs

When choosing a storage tank, the material is essential to its effectiveness. Different materials offer distinct characteristics that make them appropriate for specific applications. Consider factors such as the material you'll be storing, climate conditions, and your budget.

Commonly used storage tank materials include steel, polyethylene, fiberglass, and concrete. Each material has its own strengths and cons. Steel tanks are durable, but can be susceptible to corrosion. Polyethylene tanks are lightweight and resistant to rust, making them frequent for storing chemicals. Fiberglass tanks offer a blend of strength and corrosion resistance, while concrete tanks are sturdy.

Ultimately, the best material for your storage tank depends on your specific needs and requirements.

Hazardous Material Storage: Best Practices and Regulations

Ensuring the well-being of personnel and protecting the environment are paramount concerns when handling hazardous materials within chemical tanks. Adhering to stringent regulations is crucial for mitigating risks and preventing accidents. Key practices encompass meticulous evaluations of tank integrity, implementing robust airflow systems to minimize contamination, and establishing comprehensive disaster preparedness procedures.

- Legislative requirements governing chemical tank operations typically mandate comprehensive safety protocols, including permitting requirements for handling specific chemicals.

- Tank servicing schedules must adhere to regulatory guidelines to ensure the structural integrity and leakproof nature of the tank.

- Education programs for personnel involved in handling chemicals are essential for fostering a culture of safety and conformance.

Continuously monitoring operational parameters within the tank and its area helps identify potential hazards early on, enabling timely interventions.

Containers Types and Uses: Vertical vs. Horizontal

In the realm of industrial holding, tanks play a crucial role in safely containing various fluids. These versatile structures come in two primary configurations: vertical and horizontal, each with distinct traits suited for specific applications. Vertical more info tanks, characterized by their altitude and narrow width, are ideal for maximizing storage capacity within a limited footprint. They find widespread use in the retention of liquids like water, oil, and chemicals, often employed in applications requiring high quantity. Conversely, horizontal tanks, distinguished by their elongated form and broader diameter, are preferred for storing materials or handling large volumes of viscous fluids. Their flat foundation facilitates easy loading and unloading, making them suitable for industries like agriculture, mining, and petroleum.

- Situations of vertical tank applications include: reservoirs, fuel storage tanks, and chemical processing plants.

- Uses of horizontal tanks encompass: grain storage facilities, oil transportation pipelines, and wastewater treatment plants.

Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Judd Nelson Then & Now!

Judd Nelson Then & Now! Michael Bower Then & Now!

Michael Bower Then & Now! Romeo Miller Then & Now!

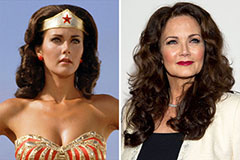

Romeo Miller Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now!